What to Expect When Getting Spray Foam Insulation Installed

Getting spray foam insulation installed in your home is beneficial in many ways. Not only is spray foam one of the most effective and energy-efficient types of insulation material, but it also helps prevent mold and mildew growth. To learn more about what to expect when installing spray foam insulation in your home, continue reading.

Preparing for the installation

After your contractor provides you with a detailed project explanation, they will prepare the application site. To ensure the workers’ safety, ventilation such as a large fan or opened windows will be arranged. In addition, all sources of ignition will be extinguished in the application site and surrounding areas, due to spray foam’s flammability. If the existing insulation is present, it may be removed before applying a new layer of spray foam insulation.

Undergoing the installation process

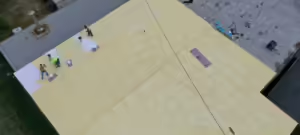

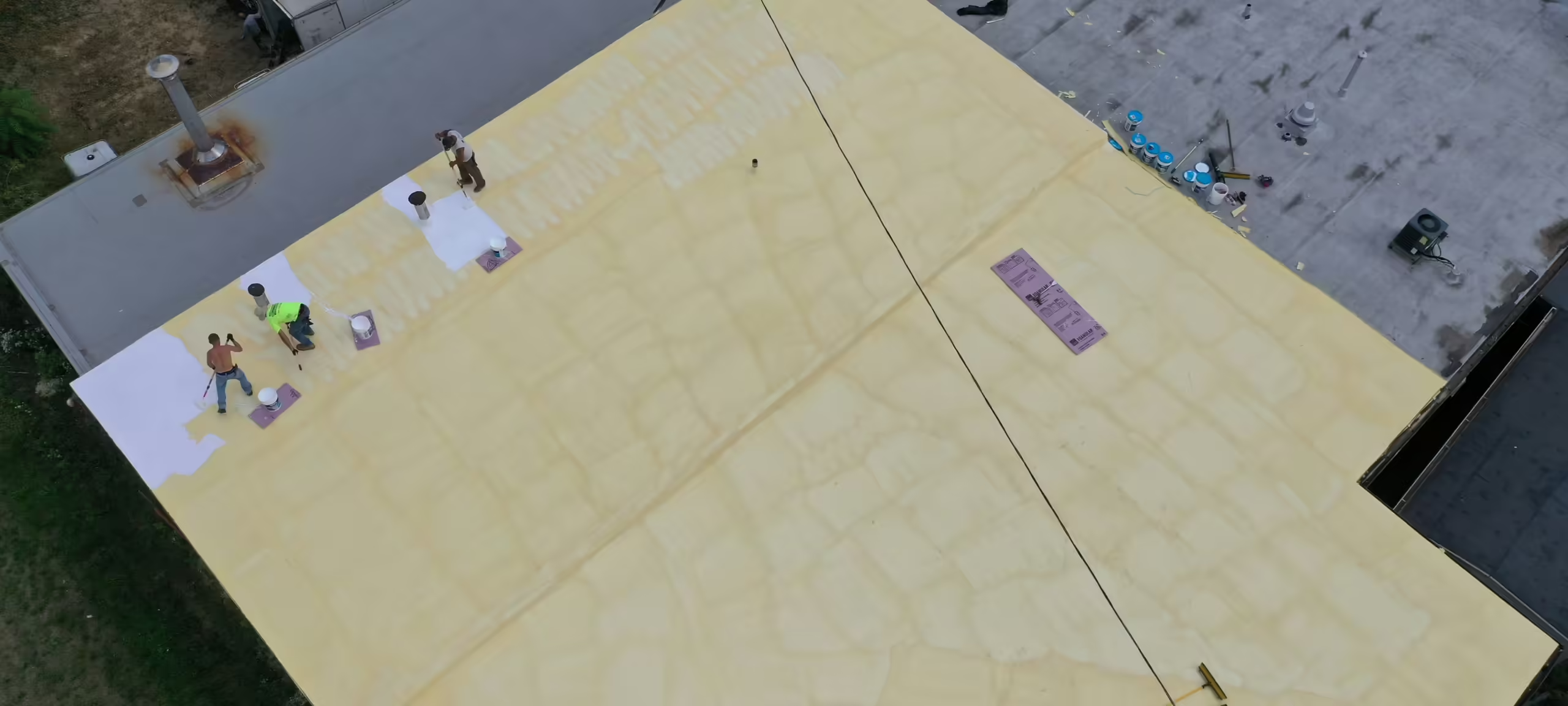

When it is time to install the spray foam insulation, contractors will set up their specialized equipment. After suiting up in proper protective gear—including eye protection, gloves, respiratory protection, and full-coverage clothing—they’ll begin the process of installing spray foam insulation. Most of the time, spray foams will be manufactured on-site. This process involves mixing and heating two liquid components—polyol resin and a form of isocyanate—which facilitates a chemical reaction that produces the spray foam. Next, the manufacturer will specify a temperature range for the materials and surfaces that they will be applied to in order to ensure optimal performance.

Using specialized equipment, the contractors will then spray the foam onto floors, windows, electrical outlets, plumbing pipes, vents, fixtures, and hard-to-reach areas. During this time, site access to the area that is being insulated will be limited to workers equipped with proper safety gear. This restriction is because the chemicals present in the spray foam insulation installation process are toxic when they are inhaled or make direct contact with the skin.

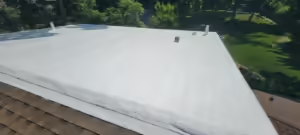

After the spray foam has been applied, it will expand to fit the shape of the surface it has been applied to. As a result, an air-tight and moisture-tight seal forms.

After the installation process

After the insulation is properly installed, contractors will thoroughly clean the worksite so that residents can safely occupy the area. They will properly dispose of materials used for overspray protection and empty foam material drums. Following the installation, you’ll be instructed not to enter the application site for a minimum of 24 hours while the foam fully cures.

If you’re looking for a trustworthy spray foam insulation company in Chicago, consider Paragon Protection. We provide high-quality insulation services to residential and commercial structures of all sizes. For more information regarding our services, contact us today.

Professional Insulation Services

Professional Insulation Services Attic Insulation Services

Attic Insulation Services Basement Insulation

Basement Insulation Commercial Insulation

Commercial Insulation Crawl Space Insulation

Crawl Space Insulation Exterior Wall Insulation

Exterior Wall Insulation Garage Insulation

Garage Insulation Interior Wall Insulation

Interior Wall Insulation Shed Insulation

Shed Insulation Power Washing

Power Washing Sealcoating

Sealcoating Backup Power Generators

Backup Power Generators Insulation Removal Service

Insulation Removal Service Lake County Insulation

Lake County Insulation Spray Foam Insulation Guides

Spray Foam Insulation Guides Insulation Guide

Insulation Guide Home Improvement & Maintenance Guide

Home Improvement & Maintenance Guide